|  |  |  |  |  |  |

|  |  |

|

|

|  |

|  |  |

|

|

|  |

|  |  |

|

|

|

|

|  |  |  |  |  |  |

ABOUT

FALMOUTH

PRODUCTS HISTORY

Falmouth Products originated in 1986 with government funded research and development projects relating to environmental cleanup.

Soil vapor extraction became accepted technology for cleaning hydrocarbon contaminated soils, and Falmouth Products focused company efforts on equipment for this emerging market.

For over thirty years Falmouth Products has manufactured electric catalytic oxidizers (FALCO’s). FALCO’s were easily installed and moved from site to site and replaced cumbersome thermal oxidizers and carbon systems.

Today, Falmouth Products continues to service the remediation, industrial process and manufacturing industries.

REMEDIATION

Soil Vapor Extraction (SVE) Equipment

INDUSTRIAL

Industrial VOC Abatement

CATALYTIC OXIDIZER

How does a

Catalytic Oxidizer (Catox) work?

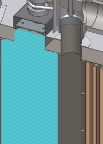

The FALCO 300 stainless steel spiral plate heat exchanger provides over 132 square feet of surface area which recovers exhaust heat to preheat incoming flow.

The temperature control system cycles electric heaters. Vapors are heated to catalytic oxidation temperature. Minimum inlet temperature for VOC’s is typically 330˚C.

The treated flow is discharged out the stack. Discharge temperature is between 125˚C and 300˚C. For more information on the catalytic oxidation process visit: HOW FALCO CATALYTIC OXIDATION WORKS

Vapors enter the catalytic oxidizer through a flame arrestor where multiple layers of stainless steel screen prevent flame propagation in either direction.

Vapors enter the catalytic oxidizer through a flame arrestor where multiple layers of stainless steel screen prevent flame propagation in either direction.

Hot vapors enter the catalyst inlet plenum and flow velocity is dropped. Catalyst inlet temperature (T1) is measured with a thermocouple.

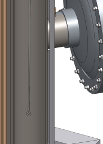

Catalyst operating temperature is between 330˚C and 600˚C. Temperature rise is measured at the catalyst midpoint (T3), and on the discharge (T2). The temperature control system receives input from all three thermocouples and regulates dilution air to control input concentrations.

Treated vapors enter the discharge portion of the heat exchanger. The heat exchanger surrounds the catalyst chamber minimizing conductive heat losses.

Vapors enter the massive packed bed catalyst and are destroyed by flameless surface combustion. Heat is released as vapors are converted into C02 and water.

The long discharge passage of the heat exhanger recovers the heat of combustion. The heat exchanger outer surfaces are insulated and protected by an aluminum jacket.

Heat recovery is adjustable: A portion of the treated flow can be diverted through a bypass valve directly to the discharge stack. Reduced heat recovery (bypass open) enables operation at high input loading. Conversely, maximum heat recovery (bypass closed) enables energy efficient operation at low input loading. A stack damper applies pressure to the discharge circuit when the heat exchanger bypass valve is opened to enhance bypass flow. When the bypass valve is closed, the damper is fully open. When the catox is off, the damper closes to reduce heat loss.

The temperature control system cycles electric heaters. Vapors are heated to catalytic oxidation temperature. Minimum inlet temperature for VOC’s is typically 330˚C.

Our Clients

Contact Us

Get In Touch

Phone number

508-548-6686

Email Address

sales@falmouthproducts.com

Office

7am - 5pm EST

200 20th Street,

Butner, NC 27509

Falmouth Products

Falmouth Products equipment is available for purchase and Rental. Used Catalytic Oxidizers (Catox's) are also available. Our engineering team is always available to discuss your specific application.

Product Recovery Management, Inc. - Falmouth Products Division. All rights reserved.

Quick Links

© 2026 Product Recovery Management, Inc. – Falmouth Products Division. All rights reserved